Elaborating new processes is one of ADIV’s trademarks, it is part of its DNA

The needs for industrial process changes are numerous and recurrent: adaptation to consumption trends, raw-material securing, product-quality control, ergonomics improvement, cobotics and reduction of arduous nature of work, and also competitiveness preservation.

ADIV offers innovative production concepts, putting forward appropriate and pragmatic solutions.

The strength of ADIV is its capacity to take up all the key steps to innovation. It is also a great combination of the technological thinking required for modifying tools and business practices and a strategic research about the adequacy and the commercial fate of the innovation.

ADIV gives its support to every company during the implementation process and industrial transfer.

Discover our flagship

technologies ?

OSMOFOOD Technology

OSMOFOOD technology can dry, pasteurize and/or continuously cook minced meat of all species in really thin layers.

Highly promising technology for joggers, walkers, athletes, but also for restaurant and catering trades, or regular consumers who can enjoy it for cocktail hour,OSMOFOOD products have already been adopted by the US ARMY.

This technology is the subject of two patents, property of ADIV.

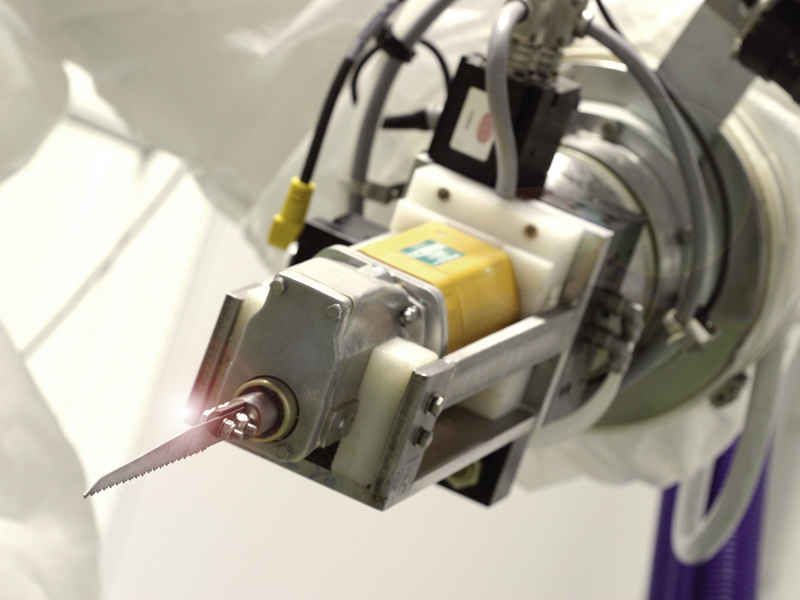

Stream dome

The aim of this innovating process is to control microbiological carcasses quality at slaughterhouses.

The Steam Dome process consists in the « Flash pasteurization » of the carcass under a Dome.

This technology has been patented in July 2011.

In 2016, ADIV has started integration and industrialization phases, in partnership with slaughtering companies.

Biopreservation

Dry-ageing process

ADIV internally developed a dry-ageing process of hanging meat. It was a double challenge: controlling the maturation to express the aromatic potential of the meat, while taking care of the microbiological and visual stabilization of the conditioned meat.

A transmission of expertise to the company Puigrenier has given birth to a high-range beef. Today, it is commercialized for mass distribution, specialized catering and also export.

Our research and

development dynamic…

A Technological Roadmap

Developed within a rapidly evolving industry context and ecosystem…

- 5 interrelated themes